Hydrocyclone Filtration System

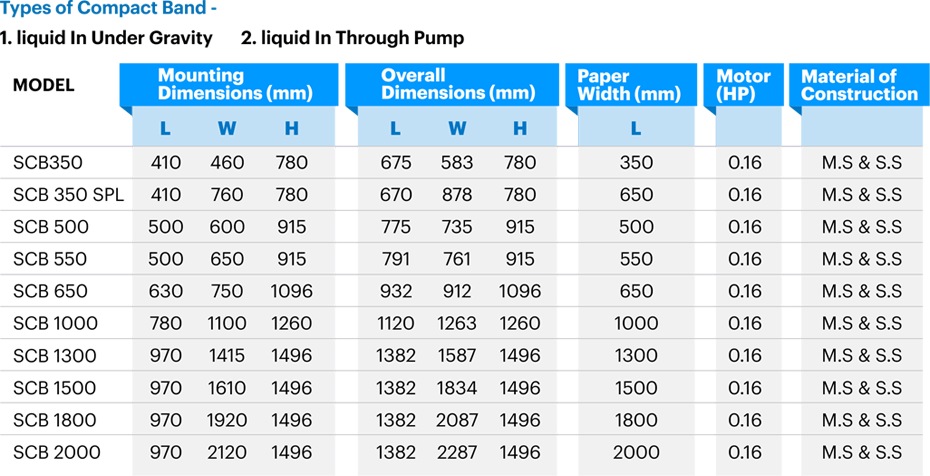

Compact Band Filtration System

Centrifuge System

Magnetic Separator

Oil Skimmer

Drum Filter

Working of Drum Filter

Drum filtration is a new filtration concept, which utilizes the force of gravity. The high hydrostatic load on the filter element allows a high quantity of liquid to pass through reduced surfaces. The filter is a rotating drum the rotation of the drum takes place by means of a dredging system activated by geared motor. Dirty coolant flows into the system through the inlet and passes through the drum. Heavy chips settle down to the bottom of the drum and are carried away by the conveyor.

The fine particles are collected in the drum. The fine particles are cleaned off the belt and carried away in the form of sludge. Span drum filter is a Self cleaning filter, which provides continuous filtration and steady supply of clean coolant. Due to its versatility it can be used for various applications such as grinding, process of removing chips, industrial processes e.g. Industrial washing machine.

Benefits

Fully Automatic filtration process

Fully Automatic filtration process

Fully Automatic filtration process

Fully Automatic filtration process

Features

- Compact design which occupies 80% less space than a flat-band filter

- Optimized filter media consumption

- Can be used to filter ferrous and non-ferrous materials

- Can be used to process water-based emulsion coolant or neat cutting oil filtration

- High filtration efficiency between 10-30 microns

- Can tackle high flow rates of 2500 to 3000 lpm