Hydrocyclone Filtration System

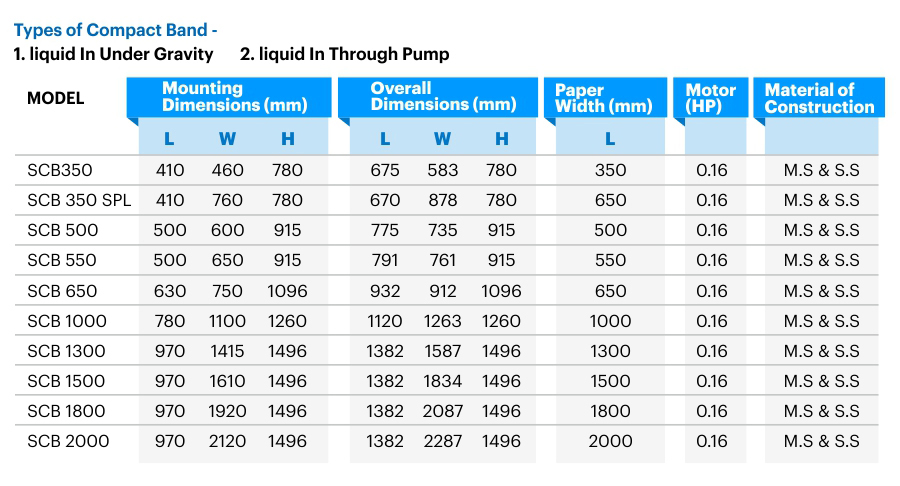

Compact Band Filtration System

Centrifuge System

Magnetic Separator

Oil Skimmer

Compact Band Filtration System

Working of Compact Band Filter

The medium to be filtered is forced to flow through the filter fleece vertically from the top to the bottom prior to entering the clean tank. The actual reservoir is formed by the filter fleece. Due to this fact it is impossible for sludge deposits to build up in corners or on the bottom of the filter, which may (does) occur in filtration systems working from bottom to top.

Damage to the filter fleece can be easily recognized from the top without dismantling. The fleece feed system acts without back tension and therefore trouble free. Because of the specific current direction in the filtration reservoir, no under pressure is necessary. High foaming liquids can be processed without difficulties, as the filtration reservoir can store a great volume of foam.

Benefits

Fully Automatic filtration process

No leaks from rupture or overflow

Stainless steel design for low maintenance

Low consumable cost

Filter paper lasts longer ensuring material & cost saving

Features

- Long-service life for paper as filter media consumption is optimal

- System is suitable for both water based emulsion and neat oil coolant

- Filters can be used to filter ferrous as well as non-ferrous metal dirt particles

- Filtration efficiency of up to 10 microns